Comfort navigation settings

The following information will provide you with an easy to navigate overview of what will happen with your personal data when you visit this website.

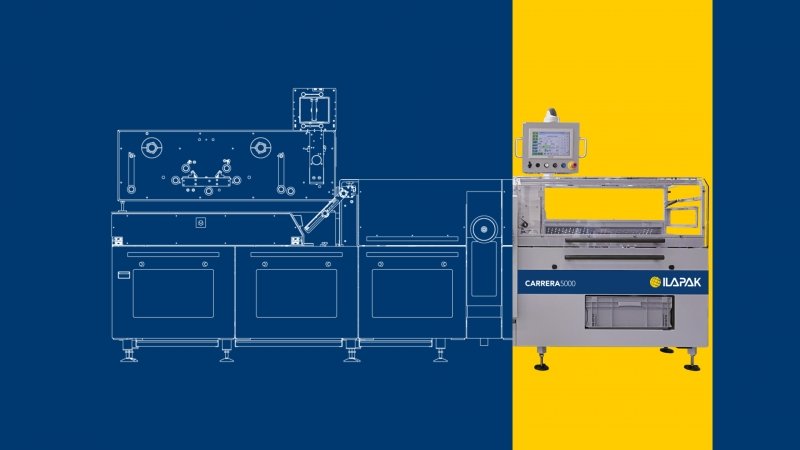

At IBA 2018, Ilapak is unveiling a brand new flow wrapper dedicated to the bakery industry. The Carrera 5000 meets demand from middle-tier bakeries for a robust, easy to maintain machine that offers the same in-line integration and performance capabilities as a top-of-the-range flow wrapper but with fewer added features.

“This is the first innovation to come out of ILAPAK’s new sector-specific R&D strategy – an approach that represents a departure from the packaging industry ‘norm’ of designing a generic machine and then adapting it for different applications. Bakery is a very important industry to us –representing approximately 50% of our customer base – so it made perfect sense that our bakery customers should be the first to benefit from this new equipment development programme,” says Alessandro Gaspari, HFFS Group Sales Manager at ILAPAK.

Marco Pocaterra, Carrera 5000 Development Team Manager, adds: “In developing the Carrera 5000, our engineers have drawn on years of bakery industry experience to create a model that is truly tailored to the demands of medium sized bakery operations. For example, these customers don’t need full washdown capabilities, so machines can be painted steel rather than stainless, but they are looking for high performance, low cost of ownership and the ability to execute maintenance and changeover routines quickly.”

The Carrera 5000 slots neatly into ILAPAK’s range between the entry-level Carrera 1000 and the high-spec, high-speed Carrera 6000. ILAPAK’s engineers have removed some of the features available on the Carrera 6000 that are superfluous to requirement for this target market and identified ways of stripping out cost without compromising build quality or performance. The Carrera 5000 is capable of 80 metres/min on cold seal films and 40 metres/min on hot seal films – matching the performance of the Carrera 6000. This has been achieved via a radical re-engineering of the machine frame that has produced the first ILAPAK flow wrapper with a tubular frame for added robustness.

In contrast with the Carrera 1500, the Carrera 5000 is engineered to be integrated into a fully automated continuous workflow, with fully automatic feeding and the option to choose from any electronic platform, whether Rockwell, Siemens, Allen Bradley or Schneider. For easy access, the control panel is located on a swivel arm – the first time ILAPAK has used a swivel on a non open frame machine.

The Carrera 5000 also incorporates several other completely new build features that are exclusive to this model and geared towards easy maintenance and changeovers. ILAPAK’s engineers have zoned the flow wrapper so that all mechanical and frequent maintenance can be carried out from the operator side of the machine. On the other side of the machine, mechanical and electrical parts are organised to facilitate access by different engineers and maintenance teams. Full cantilever construction allows easy removal of parts without tools and sealing heads are easily interchangeable.

The sealing system incorporates incremental innovations that have enabled ILAPAK to stretch the performance: price ratio of this system. Heavy duty shafts and surrounding bearings allow for greater and more consistent seal-jaw pressure; an improved jaw profile results in superior seal appearance and integrity and the use of micro-metric technology enables tool-less and repeatable adjustment of the sealing head for different material thicknesses.

The Carrera 5000 can run off pillow bags and gusseted pillow bags from film widths of up to 500mm, making it ideally suited to packaging bakery and confectionery items such as bread rolls, morning goods, chocolate bars, cereal bars and biscuits.

Fill this form to be always updated about Ilapak’s world